Roll Forming Line for Roof Panel

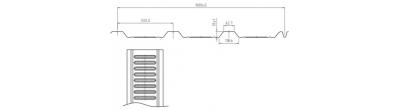

This roll forming line is designed to roll forming roof panel, it is capable of processing 0.3mm to 0.7mm thick steel coils, with full roll forming speed up to 20m per minute. We could also provide featured punching, cutting system and there are optional control system, stacker for you choose

Roll forming line for roof panel is widely used to produce roofs and walls of workshops, warehouses and steel structure buildings, provided with high reliability and durability.

Specifications| Machine Specifications | |

| Weight | About 9500kgs |

| Size | About 10m x 1.7m x 1.5m (length x width x height) |

| Color | Main color: green |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Colored Steel Coils |

| Thickness | 0.3-0.7mm |

| Coil width | 914,1220mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 22 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

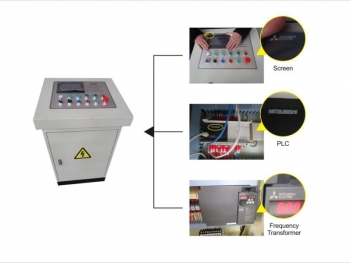

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 7.5kw |

| Hydraulic unit motor power: 3kw | |

| Electric voltage | According to customer's requirement |

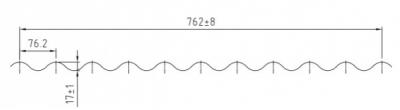

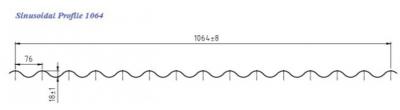

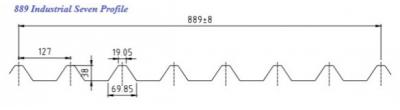

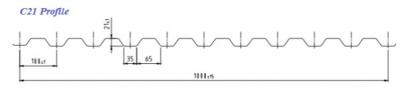

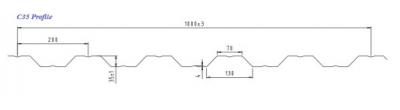

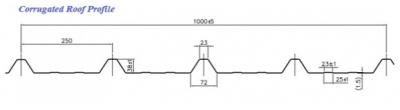

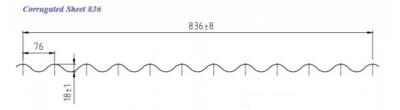

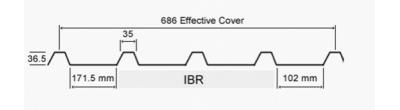

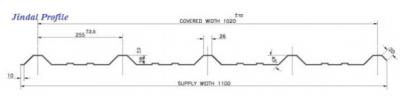

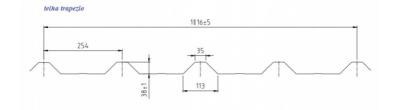

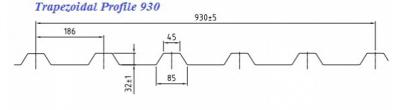

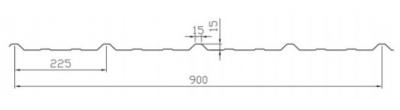

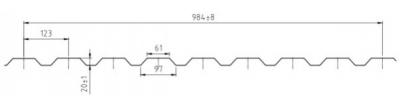

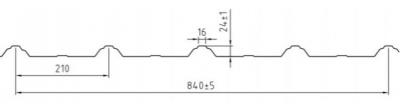

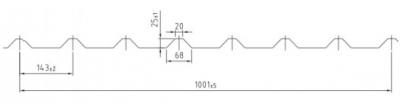

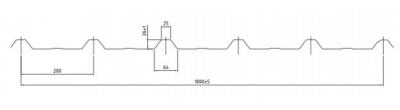

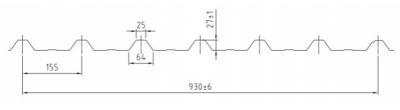

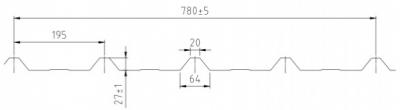

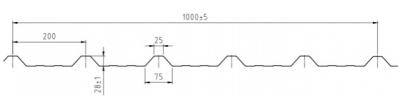

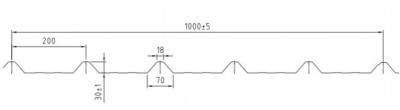

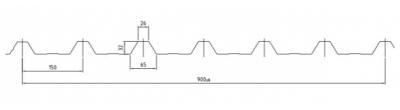

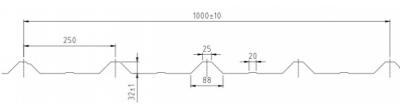

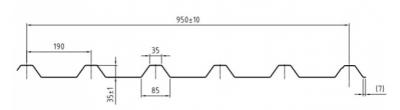

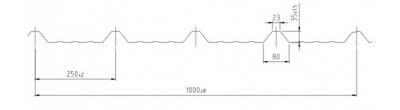

20+ standard roof panel profiles are available and we can make custom profiles according to your requirements on profile, raw material, width range and other aspects.

Gallery Wuxi JingShiRui Machinary Factory is a manufacturing enterprise backed by advanced technologies in roll forming industry. Since its establishment, JSR Machinery has been specializing in the provision of high quality high productivity

metal processing equipment for global customers. Professional knowledge along with abundant experience enable us to design and manufacture custom roll forming line benefiting your business.

Inquiry

Design and Manufacture Metal Rollforming System to Meet All Your Needs