Gutter Machine

Gutter roll forming machine is mainly used to manufacture drainage system of buildings, featured by high production precision that the profile height tolerance is controlled within 1mm. It is easy to operate, less footprint occupying, convenient for construction. Full production speed reaches up to 6m/min. Besides, made of pre-painted galvanized steel coils, our gutter roll former has longer service life than general PVC gutter roll forming machines, so it is an ideal choice for production of a variety of gutters.

JSR Machinery is confident in customizing gutter roll former according to your profile, raw material and other requirements.

Specifications| Machine Specifications | |

| Weight | About 6000kgs |

| Size | About 8m × 1.2m × 1.5m (length × width × height) |

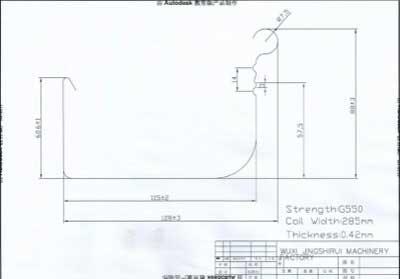

| Suitable Raw Material | |

| Material | Pre-painted galvanized steel coils |

| Thickness | 0.4-0.6mm |

| Yield strength | 235Mpa |

| Main Technical Parameters | |

| Diameter of forming roller shafts | 65mm |

| Production speed | 6m/min |

| Forming roller material | No.45 steel, chrome plated |

| Cutter material | CR12 mold steel, quenched |

| Control system | PLC and converter |

| Electric power requirement | Main motor power: 3kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer's requirement |

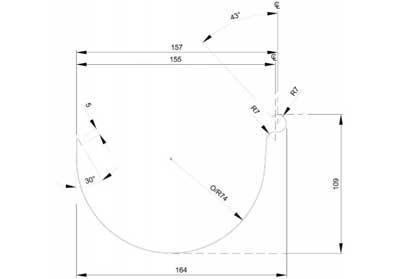

You Can Choose the Common Profiles Below or You Can Customized

Gallery

Design and Manufacture Metal Rollforming System to Meet All Your Needs