Roll Forming Line for Downspout

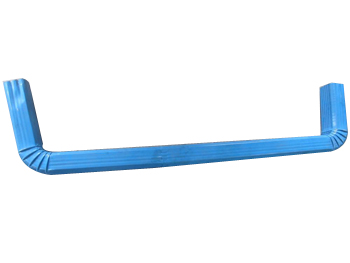

Downspout forming machine is used to manufacture downspout with a water tight seal and solid construction through cold-formed structural steel.

Cutting length tolerance: ±2mm.Shaft with the diameter of 65mm and H-shape steel under frame can offer high durability to avoid deformation.

Its roll forming system ensures the high durability and high-accuracy performance of No. 45 forged steel roller through the process of CNC grinding and hard chrome plating.

Its cutting method is achieved by metal cutting blade to ensure the flat shape of downspout and avoid its deformation.

Mitsubishi / Siemens PLC control system with ease of operation and

high reliability can ensure the machine is running steady and reliable.

| Machine Specifications | |

| Weight | About 7000kgs |

| Size | About 8m x 1.2m x 1.5m (length x width x height) |

| Suitable Raw Material | |

| Material | Pre-painted Galvanized Steel Coils |

| Thickness | 0.4-0.6mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Diameter of forming rollers shafts | 65mm |

| forming Speed | 8-10m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 4kw |

| Saw motor power: 3kw | |

| Electric voltage | According to customer’s requirement |

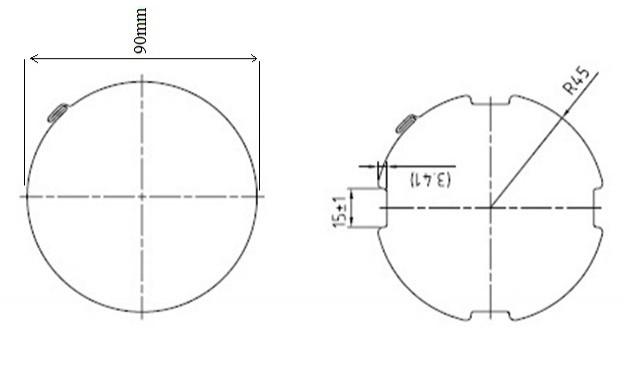

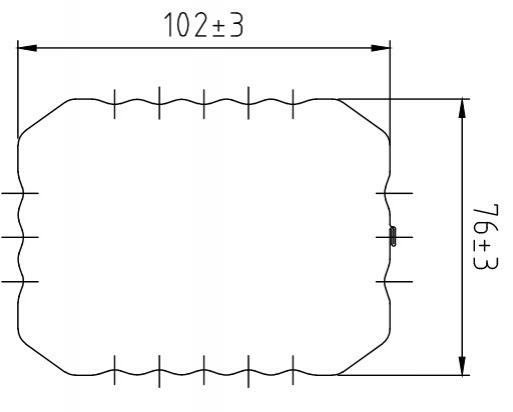

You Can Choose the Common Profiles Below or You Can Customized

Our strut channel roll forming machine can be customized according to your requirements of size and raw material. We are committed to guarantee your roll forming system top performances after commissioning. With ease to install and operate, it can start working automatically after refilled with hydraulic fluid according to the instructions. You can refer to our provided video or consult our professionals for help when you encounter any problems with installation and use.

Gallery

Design and Manufacture Metal Rollforming System to Meet All Your Needs