Roll Forming Line for Guardrail

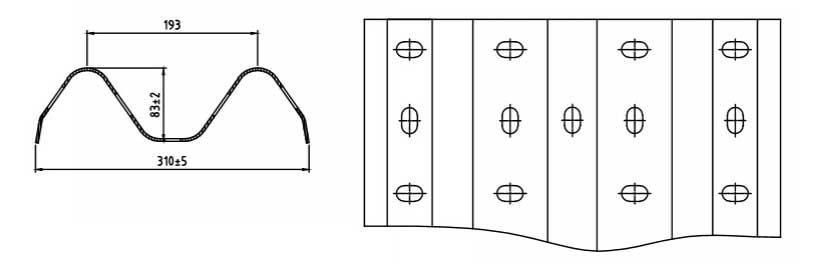

Guardrail plates are primarily applied to safety protection on both sides of roads, while our guardrail rolling forming machine can produce safer and durable guardrail plates designed with smooth edges. It is designed with gear box transmission system, along with precision rollers that can quickly form 2mm to 4mm thick steel sheets at full speed up to 15m/min. Equipped with Siemens or Mitsubishi operating system makes efficient and convenient production come true. Guardrail plates are commonly W shaped, while we can also tailor corresponding guardrail roll forming equipment depending on your demands on guardrail profile, material and other aspects.

Specifications| Machine Specifications | |

| Weight | About 18000kgs |

| Whole line's dimension | About 25m * 6m * 1.5m (length * width * height) |

| Color | Main color: Blue |

| Warning color: Yellow | |

| Suitable Raw Material | |

| Material | Galvanized or galvalume coils |

| Thickness | 2-4 mm |

| Coil width | 482 mm |

| Yield strength | 235 MPa |

| Main Technical Parameters | |

| Quantity of forming roller stations | 16-18 |

| Diameter of forming roller shafts | 90 mm |

| Roll forming speed | 10-15/min |

| Forming roller material | CR12 mold steel, with quench heat treatment |

| Cutter material | CR12 mold steel, with quench heat treatment |

| Control system | PLC and converter |

| Electric power requirement | Main motor power: 55kw |

| Hydraulic unit motor power: 22kw | |

| Electric voltage | Depending on customer's requirement |

| Main Components | |

| De-coiler (manual and automatic for options) | 1 set |

| Guiding device | 1 set |

| Leveling system | 1 set |

| Punching system n | 1 set |

| Roll forming system (with gearbox transmission) | 1 set |

| Hydraulic cutting system | 1 set |

| PLC control box | 1 set |

| Hydraulic unit | 1 set |

| Run outs tables | 1 set |

You Can Choose the Common Profiles Below or You Can Customized

-

-

-

-

<

<

Design and Manufacture Metal Rollforming System to Meet All Your Needs