Roll Forming Line for Metal Tile Roofing

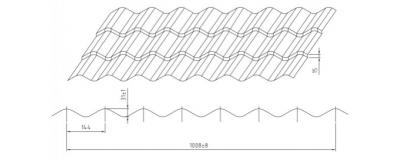

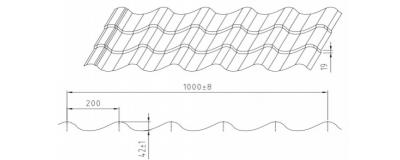

JSR provide panel roll forming line for roof tile panel, the high precision rollers can roll form 0.4mm to 0.6mm thick galvanized steel sheets with a highest production speed of 6m/min. It is easy to operate for better production control, allowing operators to master within a short time so as to improve working efficiency.

This roll forming machine is primarily applied to fabricate roof tiles of steel framing buildings, which can produce a variety of beautiful roof tile shapes while ensuring quality.

Specifications| Machine Specifications | |

| Weight | About 10000kgs |

| Size | About 10m × 1.8m × 1.5m (length × width × height) |

| Suitable Raw Material | |

| Material | Pre-painted galvanized steel coils |

| Thickness | 0.4-0.6mm |

| Coil width | 1220mm |

| Yield strength | 235MPa |

| Main Technical Parameters | |

| Diameter of roll shafts | 75mm |

| Roll forming speed | 10-15m/min |

| Production speed | 6m/min |

| Forming roller material | No.45 steel, chrome plated |

| Cutter material | CR12 mold steel, quenched |

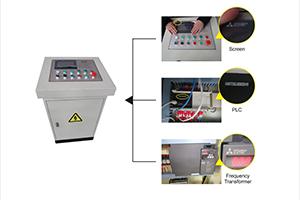

| Control system | PLC and converter |

| Electric power requirement | Main motor power: 5.5kw |

| Hydraulic unit motor power: 11kw | |

| Electric voltage | According to customer's requirement |

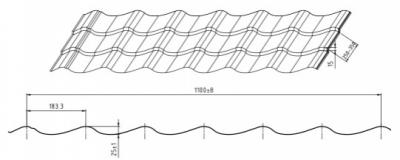

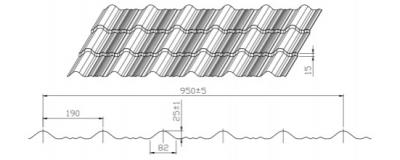

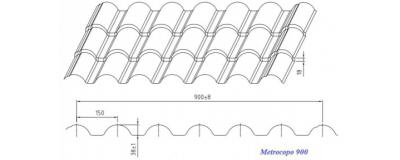

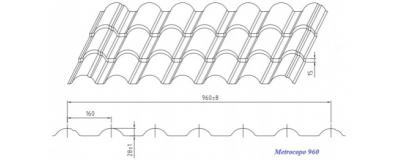

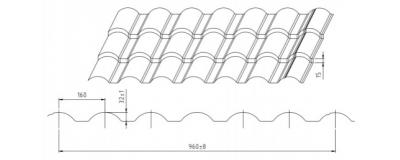

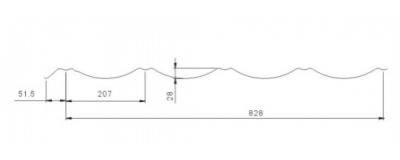

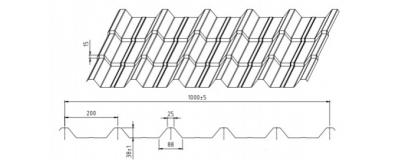

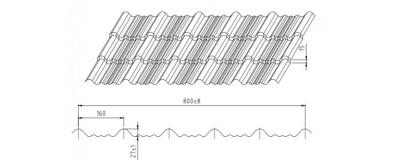

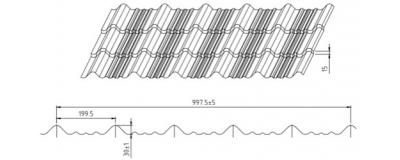

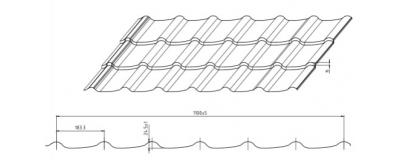

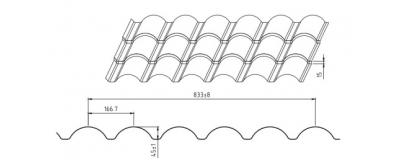

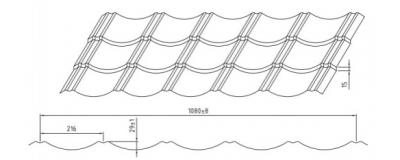

10+ standard roof tile profiles are available and we can make custom profiles according to your requirements on profile, raw material, width range and other aspects.

Gallery

Wuxi JingShiRui Machinary Factory is a manufacturing enterprise backed by advanced technologies in roll forming industry. Since its establishment, JSR Machinery has been specializing in the provision of high quality high productivity

metal processing equipment for global customers. Professional knowledge along with abundant experience enable us to design and manufacture custom roll forming line benefiting your business.

Inquiry

Design and Manufacture Metal Rollforming System to Meet All Your Needs